LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

Progress in FYE2023

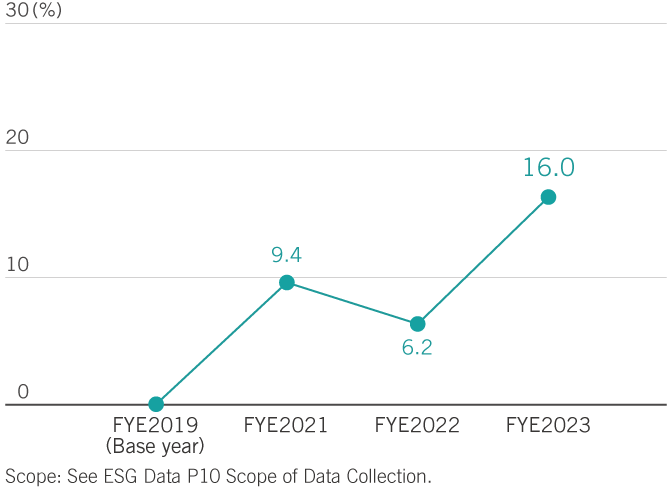

- Water use efficiency at our business sites (compared to FYE2019)

Improved by - 16.0%

- The amount of water saved by our products

- 1.5 billion m3

Our Approach

Due to the increase in global population, total household use of water has increased six-fold since 1960.*1 By 2050, 40% of global population is likely to experience water stress.*2 Indeed, in 2022, 2.2billion people did not have access to safely managed drinking water.*3 *4

In order to realize the circular economy, set forth in LIXIL’s Environmental Vision, we have designated water sustainability as one of our focus areas and positioned that goal as a priority among our material issues. As a leading company in water-related products, we will pursue water sustainability by promoting responsible use of it in our operations and providing safer, delicious drinking water so that everyone, including future generations, can fully enjoy the benefits of this resource.

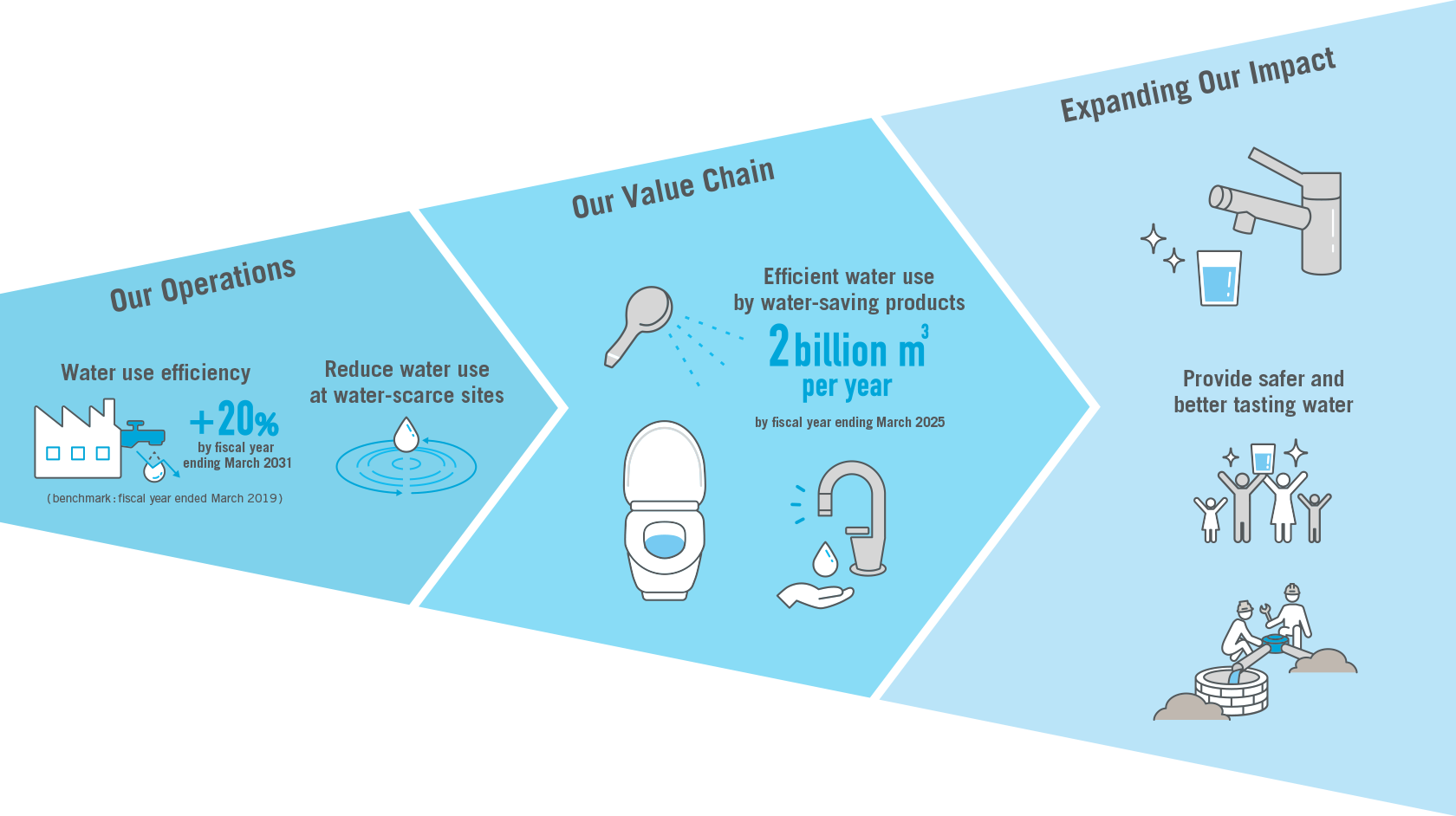

To achieve our goals, we are taking a comprehensive strategic approach and pursuing medium-term targets through each of three phases: Our Operations, Our Value Chain, and Expanding Our Impact. We will go beyond simply fulfilling our corporate responsibility to minimize the environmental burden of our business and products, and also create new value in the environmental field together with all stakeholders in order to have an even greater positive impact on the global environment and society.

Defining Our Strategic Approach and Medium-Term Targets

*1 World Resource Institute (A new page will open) >

*2 Indiatimes (A new page will open) >

- ・drinking water accessible on premises

- ・drinking water available when needed

- ・drinking water free from faecal and chemical contamination

- ・drinking water from improved sources which include;

- ・Piped supplies

- - Tap water in the dwelling, yard or plot, including piped to a neighbor

- - Public taps or standpipes

- ・Non-piped supplies

- - Boreholes/tubewells

- - Protected wells and springs

- - Rainwater

- - Packaged water, including bottled water and sachet water

- - Delivered water, including tanker trucks and small carts/tank/drum

- - Water kiosk

Our Operations

LIXIL promotes responsible water use in our operations globally, and aims to improve water use efficiency at our business sites by 20% by FYE2031 compared to FYE2019. At sites that use water for manufacturing, we work to identify related business risks in each region and take appropriate steps to recycle and manage wastewater, particularly at sites that suffer from water shortages, in efforts to improve efficiency and reduce usage.

Improving Water Use Efficiency

LIXIL promotes the utilization of recycled water in order to effectively use this resource. In FYE2023, we used approximately 660,000 m3 of recycled water.

We will also continue to increase our use of recycled water and reduce water consumption at plants in the Asian and North American regions where water shortages are severe.

Increase in efficient water use at our business sites (vs. FYE2019)

Initiatives at Sites with Water Risks

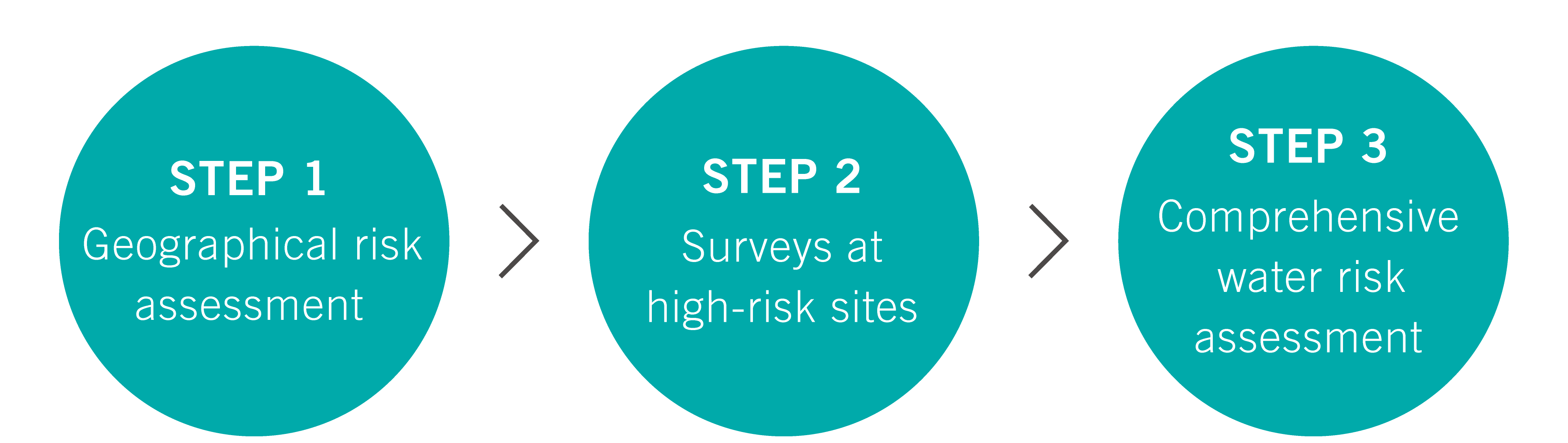

Water Risk Assessment Process

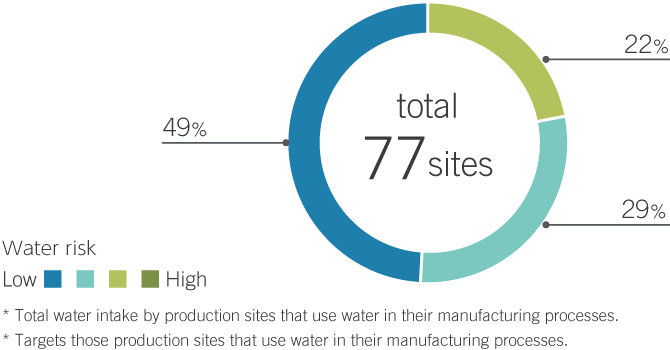

In order to better understand local conditions and introduce appropriate measures to address the problem of increasingly scarce global water resources, LIXIL started conducting surveys in FYE2017 to identify water risks at 77 production sites that use water in their manufacturing processes. Our risk assessment process involves first creating a geographical risk profile using the international WWF Water Risk Filter assessment tool. We then conduct surveys of sites that are revealed to be high-risk. This approach enables us to perform comprehensive water risk assessments.

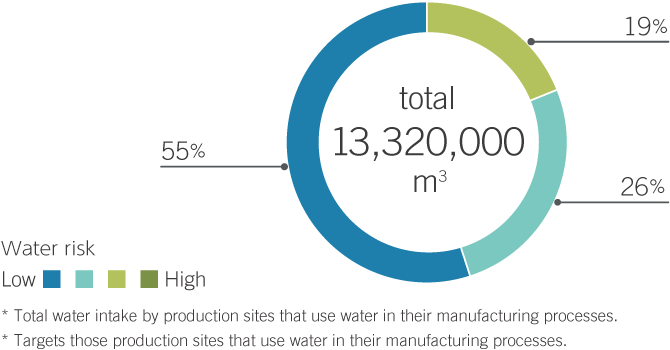

We also participate in the Corporate Engagement Program run by the Science Based Targets Network (SBTN) and help formulate guidelines surrounding water risk assessments. In FYE2023, we referenced the methods indicated by SBTN to survey risks related to water volume (water stress) and impact (water intake) in the basins surrounding our production sites (see graph below for survey results). Going forward, we intend to regularly update our analysis and to plan and implement appropriate measures in each site to further reduce risks.

At our plant in Thailand with high risk of water shortages, in FYE2023 we installed a water recycling system that utilizes rainwater and plant wastewater, and continually optimized our water use, which has reduced industrial water use by approximately 24,800 m3 annually compared to FYE2022.

Percentage of Production Sites by Water Risk Level* (As of March 2023)

Percentage of Water Intake by Water Risk Level* (As of March 2023)

Our Value Chain

LIXIL aims to contribute to a global reduction of two billion m3 per year in water consumption by FYE2025 through various products and services such as energy- and water-saving faucets and water-saving toilets. We also help reduce the water consumption by end-users not only through our products and services but also through IoT-enabled water leakage prevention solutions such as smart controllers.

Total water savings from energy- and water-saving faucets and water-saving toilets

・SATIS (INAX brand)

It achieves considerable water savings while delivering strong cleaning performance. It can save up to 49%* of water used compared to conventional toilets that use eight liters of water for each long flush. Its AQUA CERAMIC sanitaryware material repels waste during each flush, making day-to-day cleaning easier and keeping it sparkling like new for 100 years.*

* Please refer to the product website for more details on the product’s features (Japanese only, a new page will open) >

Water-saving toilets (Japanese only, a new page will open) >

SATIS (INAX brand)AQUA CERAMIC

・Studio S (American Standard brand)

It meets strict criteria for water saving established by the US Environmental Protection Agency’s WaterSense program, and can save over 20% more water than the standard criteria set by the government organization. The American Standard brand also provides products that meet the California Green Building Standards (CALGreen), which mandate the conservation of water. In addition, the bowl height of these toilets conforms to the accessibility height guidelines as outlined by the Americans with Disabilities Act of 1990.

American Standard water-saving toilet (A new page will open) >

Studio S Low-Profile Toilet

・Everstream (GROHE)

Using a shower system that recycles water makes it possible to cut water use by a maximum of 75%, reduce the energy used to heat the water by up to 66%, and also eliminate CO2 emissions by up to 70%. GROHE has set the ambitious goal of making all of its concealed shower systems recycling-enabled by 2030, and in FYE2023 announced this product as its first offering, with a planned launch in spring 2024.

GROHE Everstream (A new page will open) >

Water-recycling shower system (A new page will open) >

GROHE Everstream

・Suru (GROHE)

This smart remote-control device links together with a smartphone app to notify users of a leaking pipe or other related problems and turn off the water supply to help prevent issues in the home, which in turn helps reduce water usage.

Expanding Our Impact

LIXIL is working to reduce the risk of groundwater contamination by increasing access to safely managed sanitation services and safer water. We strive to ensure water sustainability by introducing water purification faucets and cartridges in areas that do have access to tap water to provide safer and better-tasting water.

LIXIL Public Partners (LPP) Water and Sanitation Initiatives

Our new LIXIL Public Partners (LPP) is an organization that seeks to strengthen cooperation between the public and private sectors in the field of water, sanitation, and hygiene. LPP is currently conducting trials to introduce wastewater-treatment facilities and water-efficient fixtures and fittings in rural areas of the US without access to public sewage systems. Through these trials, we are working to reduce the risk of groundwater contamination by increasing access to safely managed sanitation services and safer water, as well as aiming to accelerate the expansion of the public-private partnership model globally in the future.

Purification Technology to Provide Safer, Better-Tasting Drinking Water

As one of the few companies in the world with its own proprietary faucet and water purification technologies, we have developed a compact and highly effective filter for faucet-integrated water purifiers and other high-performance products, and have established a competitive advantage in the market. We are pressing ahead with our efforts to develop standout water-purifying products for global deployment by developing more advanced technologies that are tailored to individual markets at our X-Water Fab Tokoname (Tokoname, Aichi) and X-Water Lab Tokyo (Tokyo) water-purification research and development sites in Japan and at other bases around the world.

・Saybrook Filtered Kitchen Faucet (American Standard brand)

It uses high-grade filtration technology that can remove impurities such as lead, chlorine, and small particles contained in tap water to provide safer drinking water, with an improved taste. It comes with a small, innovatively designed filter that can be installed for easy access above deck at countertop level or below deck on the inside wall of the cabinet. Easy access to clean water helps prevent plastic water bottle usage and home water delivery, helping to reduce the environmental footprint.

Saybrook Faucet

・GROHE Blue (GROHE brand)

It is a household water system that can dispense chilled or carbonated water from the kitchen faucet. It can also chill room-temperature water to a desired temperature. Given that as much as seven liters of water is required to produce a single liter of bottled drinking water, GROHE Blue also reduces the use of water resources. Compared to using bottled drinking water, the system also helps cut up to 61% of annual CO2 emissions* generated in the manufacturing and shipment of plastic bottles, and reduces plastic waste.

* Please refer to the product website for more details on the product’s features (A new page will open) >

GROHE Blue (A new page will open) >

GROHE Blue