LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

Environmental sections of our website are to be updated in August 2024

Progress in FYE2023

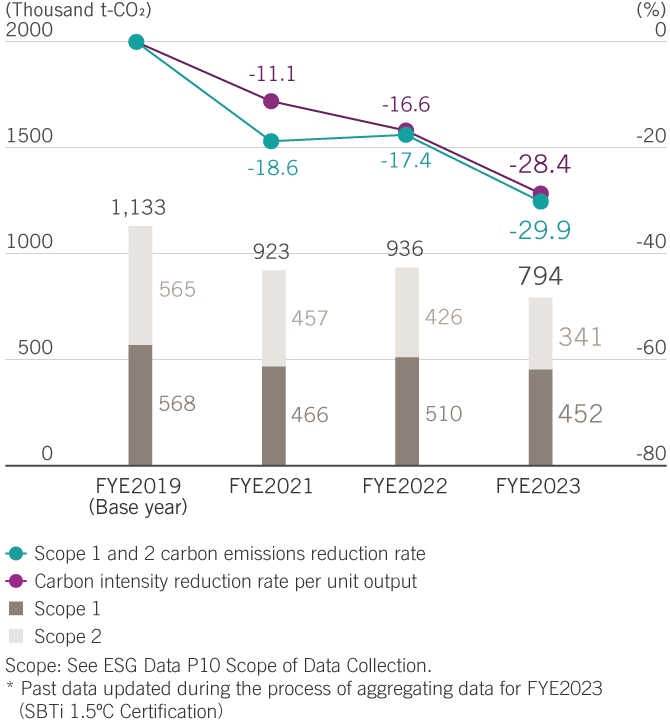

- CO2 emissions from Scope 1 and 2 (compared to FYE2019)

- 29.9% reduction

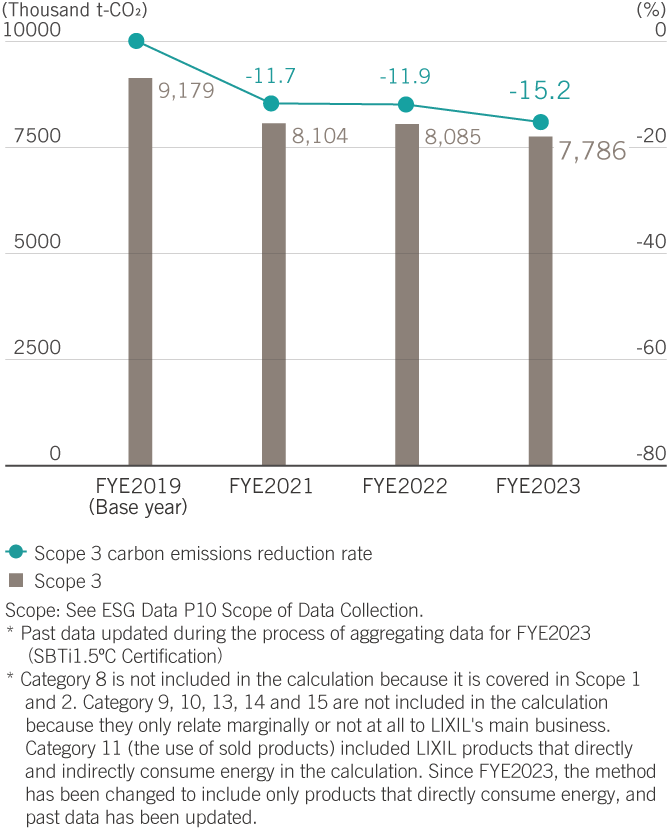

- CO2 emissions from Scope 3 (compared to FYE2019)

- 15.2% reduction

- The sales ratio of high-performance windows for detached houses (Japan)

- 90%

- The sales ratio of energy- and water-saving faucets (Japan)

- 92.2%

- The sales ratio of water-saving toilets (Japan)

- 99.2%

Our Approach

Nineteen percent of global energy-related CO2 emissions are from direct emissions by building construction and materials industries, and another 18% are due to indirect emissions from buildings and homes in use.*1 To realize LIXIL Environmental Vision 2050 ”Zero Carbon and Circular Living”, we have designated Climate Change Mitigation and Adaptation as one of our focus areas and a priority among in our material issues. LIXIL set long-term targets to reduce CO2 emissions to net zero by 2050 by reducing the environmental burden of our operations and by providing environmentally sound products and services. This long-term target became the first in the Japanese building materials industry to receive SBT Net Zero approval in March 2024.*2

LIXIL's commitment to reducing CO2 emissions is not limited to our business processes, products, and services, but extends across society. We provide solutions for users to take measures against natural disasters or to prevent heat stroke, helping them adapt to climate change.

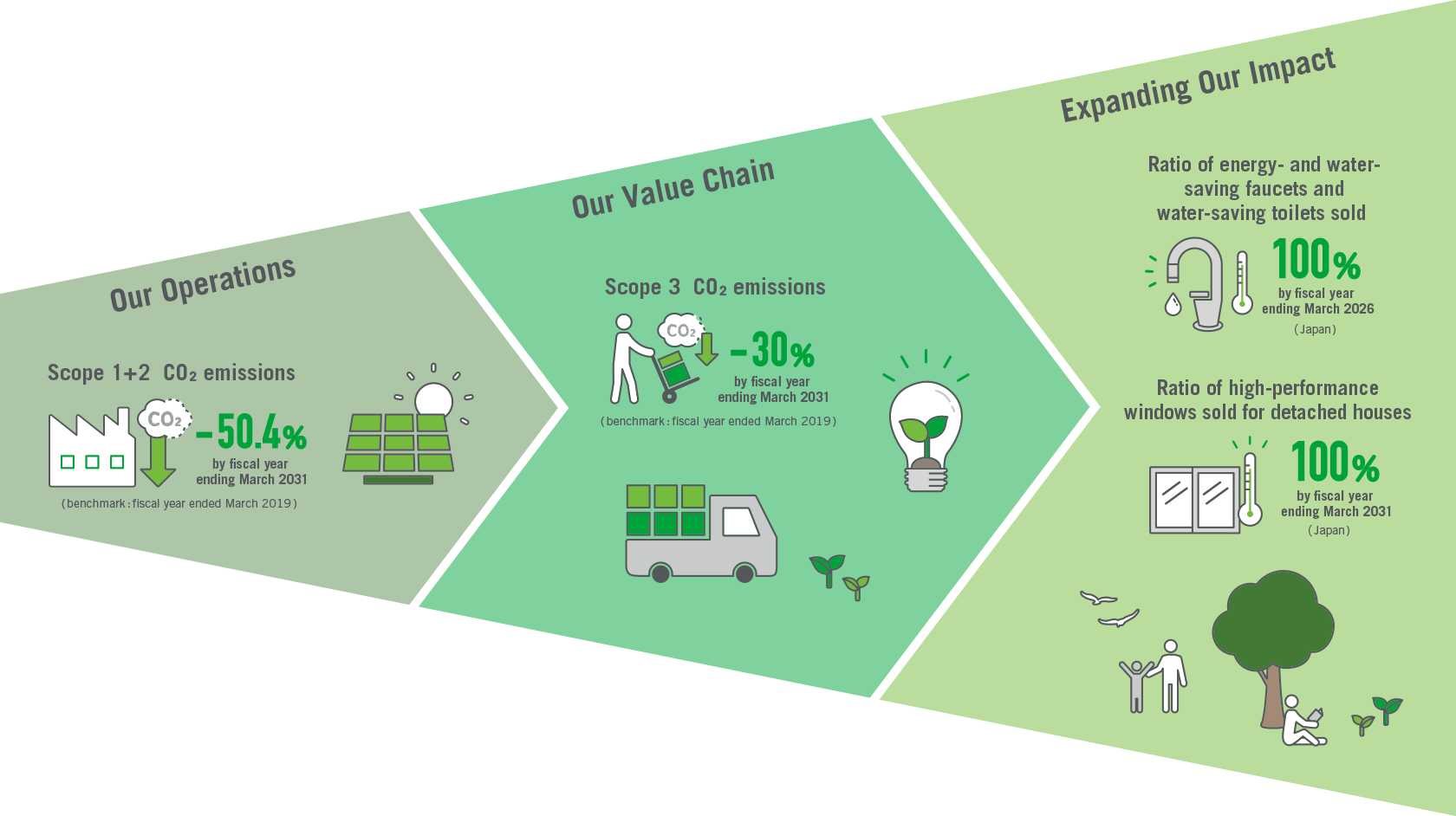

To achieve our targets, in 2024 we announced our Transition to a Low-Carbon Society which defines measures and actions for each of the three phases: Our Operations, Our Value Chain, and Expanding Our Impact. LIXIL’s comprehensive approach includes mid-term targets that go beyond fulfilling its responsibilities by minimizing the environmental burden of its business activities; but also for advancing efforts to create new value in the environmental field with our stakeholders for a greater impact on the environment and society.

*1 UNEP (A new page will open) >

Defining Our Strategic Approach and Medium-Term Targets

Our Operations

By FYE2031, we aim to reduce CO2 emissions from our business sites (Scope 1 and 2) by 50.4% compared to FYE2019. In order to minimize the environmental burden of our business activities, we are working to reduce CO2 emissions through thorough energy-saving activities at our factories and offices, and by using renewable energy, converting to fuels with low CO2 emissions, and shifting to electric power (electrification).

Scope 1, 2 CO2 emissions

Promoting Energy Efficiency, Electrification, and Fuel Conversion at Production Sites

Aging aluminum parts using hydrogen combustion

We are striving to improve energy efficiency by identifying any issues with our production processes, reviewing facilities, and generally improving activities at each production site. All factories that manufacture GROHE products and all GROHE distribution centers have received ISO 50001 certification for their energy management systems.

LIXIL’s manufacturing processes use a lot of fuel to satisfy the need for heat when manufacturing products from materials, so we are working to reduce CO2 emissions generated by fuel usage. In the low-temperature range, we are actively converting from fuel to electricity and switching to renewable energy sources. We have also started to switch the fuel used at our Ariake Plant from petroleum-based fuels to natural gas. Using natural gas emits less CO2 during combustion and less nitrogen oxide (NOx), which is an air pollutant, and does not emit sulfur oxide (SOx).

However, we need to promote innovation for manufacturing processes in the high-temperature range that goes beyond conventional fuels and manufacturing methods. With that in mind, LIXIL has started considering innovations that incorporate new technologies such as hydrogen fuel conversion and carbon capture and utilization (CCU) that separates, captures, and effectively uses CO2, as well as the application of new technologies that are currently in the research stage, with a view to practically applying such technologies from 2030 onward. In FYE2023, we successfully completed hydrogen combustion tests at our Maebashi Plant.

While there are several major hurdles relating to the development of infrastructure for supplying hydrogen as a fuel, LIXIL has started technical verification relating to hydrogen procurement with the aim of establishing technologies across all processes from procurement through usage. Indeed, in verification tests on the surface treatment process of applying color to the aluminum parts being manufactured at our Oyabe Plant, we successfully recovered over 90% of the hydrogen generated.

Transition to Renewable Energy

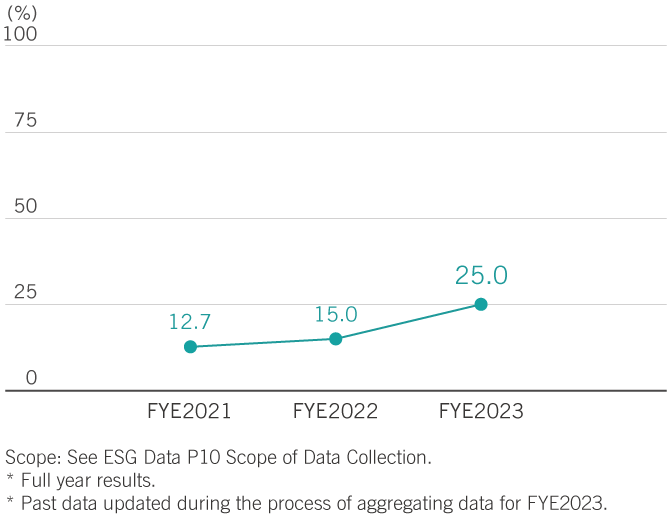

Ratio of renewable energy used

Klaeng plant in Thailand

LIXIL is making the transition to renewable energy. That drive includes our membership of RE100, a global initiative of companies committed to sourcing 100% renewable electricity for their operations.

So far, we have successfully switched to renewable electricity at 14 production sites, six offices, 10 distribution centers, and 82 sales bases in Japan. Outside of Japan, in addition to all LIXIL International faucet fitting plants and distribution centers (10 locations in total), three plants in Mexico also switched to renewable energy. In FYE2023, our renewable energy ratio reached 25.0%, cutting annual CO2 emissions by 103,600 tons from the previous year.

In addition to purchasing renewable energy certificates, we started introducing solar power generation facilities at our manufacturing plants based on the on-site Power Purchase Agreement (PPA) model* that considers additionality, or the encouragement of further investment in renewable energy facilities. We are developing on-site PPAs inside and outside Japan. For instance, the two plants that produce GROHE products generate approximately 6,500 MWh of electricity. Our Klaeng plant in Thailand, one of the two GROHE plants, installed 3.2 MW solar panels on its rooftop, cutting annual CO2 emissions by approximately 2,400 tons. GROHE also installed new solar power generation facilities at its Hemer Plant in Germany in FYE2023. The area occupied by the solar power generation system at the Hemer Plant spans approximately 20,000 m2, making it the largest in the region, and the amount of power it generates annually is equivalent to roughly 20% of the plant’s annual electricity consumption. In Japan, we started operating an on-site PPA model at our Otani Plant and plan to launch a similar model at our Onomichi Plant in August 2023. In FYE2023, we introduced off-site PPA for the first time at our four plants in Mexico. We also operate megawatt-scale solar power plants that produce approximately 34,000 MWh of power per year at eight locations in Japan.

* A business model that enables PPA service providers to install solar power generation facilities on the premises and rooftops of buildings owned by electric power consumers, and to sell electricity generated from those facilities to electric power consumers.

Our Value Chain

By FYE2031, we aim to reduce Scope 3 CO2 emissions by 30% (SBT WB 2°C level*) compared to FYE2019. Product use and procurement account for a large proportion of Scope 3 CO2 emissions across the LIXIL value chain, so, in addition to our efforts to increase the energy-saving features of our products, we are also working with suppliers and other companies to reduce CO2 emissions in the procurement and distribution phases. We reduce CO2 emissions across the entire lifecycle of our products and services by using more low-carbon raw materials and components, utilizing recycled materials, creating resource-saving products, and designing products with a view to extending product life and facilitating product reuse.

* The well below 2°C target of the Science Based Targets initiative (SBTi) to cap global temperature increase well below 2°C compared to pre-industrial temperatures

Scope3 CO2 emissions

Reducing CO2 Emissions from Procurement

Cooperating with suppliers is vital when seeking to reduce CO2 emissions in the procurement stage. We ask our suppliers for their full comprehension and cooperation in our procurement activities that are conducted internationally in accordance with LIXIL’s environmental activities and Supplier Code of Conduct, along with the additional Green Procurement Guidelines in Japan.

From FYE2023, we began engaging with suppliers that constitute the top 80% of total CO2 emissions from procurement to help us grasp current conditions across the entire value chain and reduce CO2 emissions effectively. We conducted surveys of suppliers that are particularly significant when it comes to reducing CO2 emissions to get a better understanding of total CO2 emissions and the setting of CO2 reduction targets. Going forward, we intend to increase communication based on the survey results to ensure stable supply of raw materials and responsible procurement, to facilitate the acquisition and utilization of supplier data, and to strengthen partnerships to help reduce CO2 emissions from procurement. We will also accelerate efforts to achieve effective reductions in CO2 emissions across our value chain by utilizing more low-carbon raw materials and components, and recycled materials.

Reducing CO2 Emissions from Distribution

In FYE2023, we increased operation of our round-trip shipping container program that allows shared use of logistics equipment with other companies. We achieved round-trip use of 826 containers in total with our partners, reducing CO2 emissions by approximately 107 tons a year.

Our Hokkaido Distribution Center addressed the issues of declining loading efficiency and a driver shortage by combining freight with other companies in the same industry. In FYE2023, the initiative expanded the target area to cover all across Hokkaido, and successfully reduced the combined driving distance by partner companies by approximately 590,000 kilometers a year and CO2 emissions per tonne-kilometer by 21%.

Providing Energy-Saving Products that Help Reduce CO2 Emissions During Product Use

LIXIL helps reduce CO2 emissions by offering energy-saving toilet and kitchen-related products. For example, one of our toilet products, the Satis S Type Toilet, reduces CO2 emissions by 111 kg per year by offering various functions including the Super Power-Saving Function, which automatically lowers the temperature of the toilet seat and hot water to conserve energy when not in use, and the One-Touch Power-Saving Switch, which enables the user to turn off the heater for set periods and consequently conserve energy.

Energy-Saving Products (Japanese only, a new page will open) >

Energy-saving toilet image

Expanding Our Impact

We have set targets to increase the sales ratio of high-performance windows for detached houses to 100% by FYE2026, and the sales ratio of energy- and water-saving faucets and water-saving toilets to 100% by FYE2031. In Japan, heating, cooling, and hot water account for about 60% of the energy consumed by the average home. To address this issue, we are seeking to expand our impact to mitigate climate change by providing highly insulated windows and front doors; introducing high-performance construction methods for reinsulating entire homes including walls, ceilings, and floors; providing energy- and water-saving products; offering products with energy-creating functions and associated services; and producing IoT-driven delivery boxes. We also pursue climate change adaptation by providing solutions that help improve preparedness for natural disasters, such as typhoons and torrential rains, and heatstroke due to extreme heat.

Developing High-Grade Thermal Insulation Products

・TW triple-glazed high-performance hybrid window (TOSTEM brand)

This hybrid structure window exploits the benefits of strong, durable aluminum on the outer side and resin that boasts strong thermal properties and reduces condensation on the inner side. It boasts an overwhelming high insulation performance thanks to its high-performance, gas-filled double hollow layer and cutting-edge triple-glazed, double Low-E specification. Heat loss can be reduced by approximately 80% when using a triple-glazed high-performance window compared to a single-glazed window, reducing CO2 emissions from a newly constructed house by 37%. By offering a high degree of thermal insultation, it reduces the amount of energy used for heating and air-conditioning and helps reduce CO2 emissions.

TW

・Thermal insulation renovation method for existing homes

Our Marugoto Dannetsu Reform is a high-performance housing construction method to reinsulate entire homes by improving the thermal insulation performance of walls, floors, ceilings, and openings, while utilizing the structure of existing homes. It helps improve energy-saving properties of existing houses by renovating homes to become high-performing, without a need to rebuild a house from scratch. Our scheme to support the installation of superior whole-house insulation using our Super Wall construction method has won the Agency for Natural Resources and Energy Commissioner’s Award at the 2021 Energy Conservation Grand Prize.

Winning award for our Super Wall construction method (Japanese only, a new page will open) >

Marugoto DannetsuReform

Developing Water- and Energy-Saving Faucets

・Navish Hands-Free faucet (with Eco Sensor) (INAX brand)

The Navish Hands-free faucet is a touchless faucet for the kitchen with a built-in water purifier that enables you to access your preferred type of water by choosing between two touchless sensors for purified water or regular tap water. It saves energy and water through touchless functionality that enables water to be dispensed and stopped using an automatic sensor, and Eco Sensor functionality that separates hot and cold water. The sensor helps prevent unintended use of hot water, allowing users to save approximately 37% energy* and 30% water* compared to conventional faucets.

Navish Hands-Free faucet

* Please refer to the product webpage for more details on the product’s features (Japanese only, a new page will open) >

Water- and energy-saving products (Japanese only, a new page will open) >

・GROHE EcoJoy (GROHE brand)

The GROHE EcoJoy technology facilitates water and energy savings and is available on numerous models of showers across most of all style and price segments. The integrated flow restrictor automatically reduces water consumption by approximately 50%.

GROHE EcoJoy

Climate Adaptation Solutions

・External Style Shade sun blinds (TOSTEM brand)

It blocks approximately 80% of the sun’s heat on the outside and reduce indoor temperature by as much as 3.5ºC,* cutting energy use for air conditioning and preventing indoor heatstroke.

* Please refer to the product webpage for more details on the product’s features (Japanese only, a new page will open) >

Climate-change adaption products (Japanese only, a new page will open) >

Style Shade

・Residential Window Shutter (TOSTEM brand)

It can protect against or mitigate damage from natural disasters. Benefits include preventing damage to and the scattering of window glass caused by flying debris during typhoons, and reducing the risk of the roof flying off when strong winds blow into the room.

Disaster mitigation products (Japanese only, a new page will open) >

Residential Window Shutter