LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

Environmental sections of our website are to be updated in August 2024

Progress in FYE2023

- Recycling rate of waste (across company)

- 88.1%

- Recycled aluminum used rate

- 74%

Our Approach

With the world’s growing population, global consumption of resources is expected to double by 2050.*1 In order to realize our Zero Carbon and Circular Living environmental vision, LIXIL has designated circular economy as one of our focus areas and positioned that goal as a priority among our material issues. In order to ensure the sustainable use of limited resources, we are promoting circular production across the entire product lifecycle, from procurement of raw materials, including metals, timber, resin, and ceramics, through to manufacturing, product use, disposal, and recycling, by promoting sustainable use of raw materials and easy-to-recycle design. While the amount of plastic waste has more than doubled worldwide over the past 20 years, the recycling rate remains at a stubbornly low 9%.*2 Fueled by the LIXIL Plastics Action Statement announced in FYE2021, we are also working to reduce the amount of plastic we use, to recycle plastic, and to develop alternative materials.

LIXIL Plastics Action Statement (A new page will open) PDF: 1.3MB >

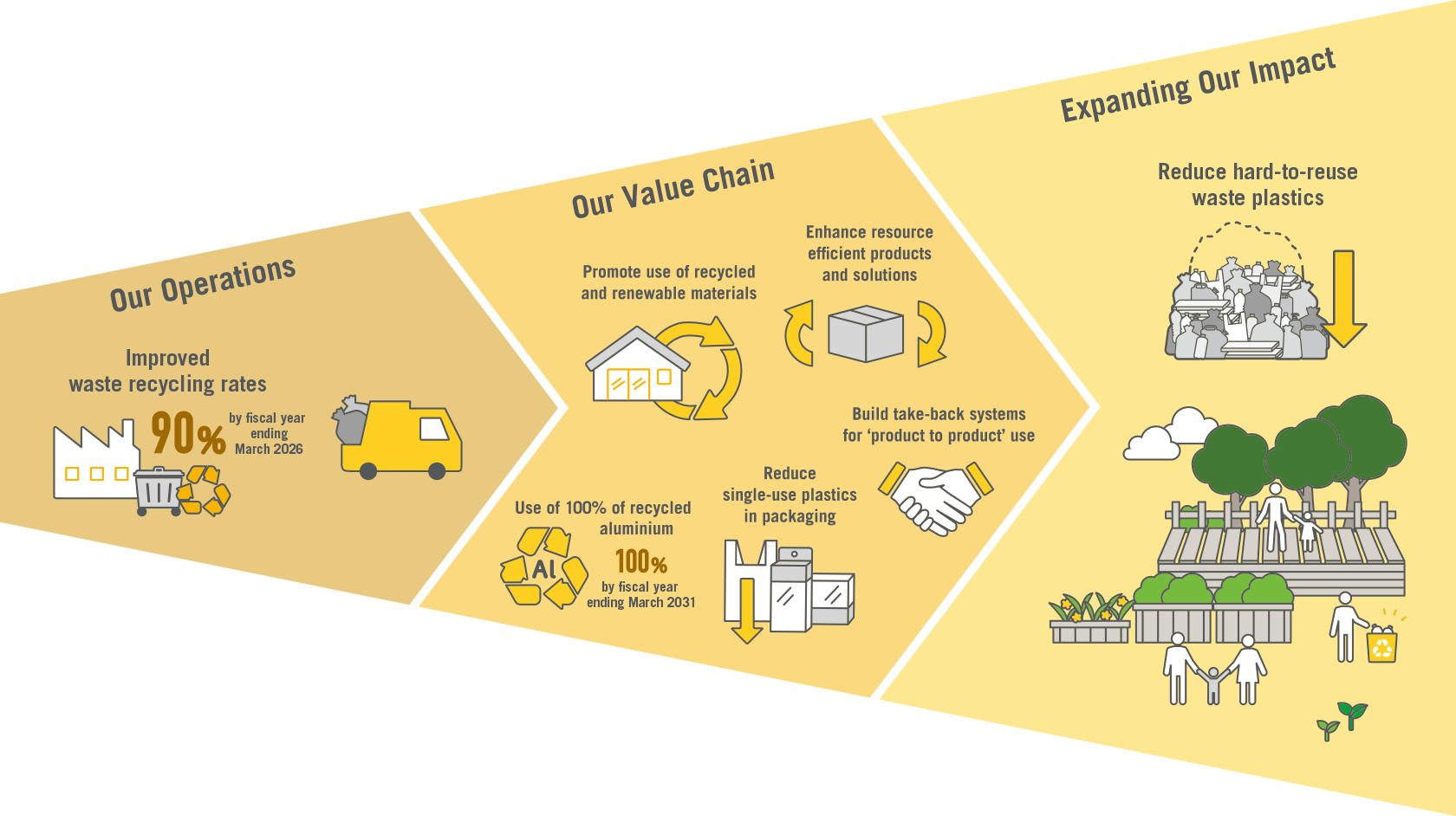

To achieve our goals, we are taking a comprehensive strategic approach and pursuing medium-term targets through each of three phases: Our Operations, Our Value Chain, and Expanding Our Impact. We will go beyond simply fulfilling our corporate responsibility to minimize the environmental burden of our business and products, and also create new value in the environmental field together with all stakeholders in order to have an even greater positive impact on the global environment and society.

*1 UNEP (A new page will open) >

*2"Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options" by OECD (A new page will open) >

Defining Our Strategic Approach and Medium-Term Targets

Our Operations

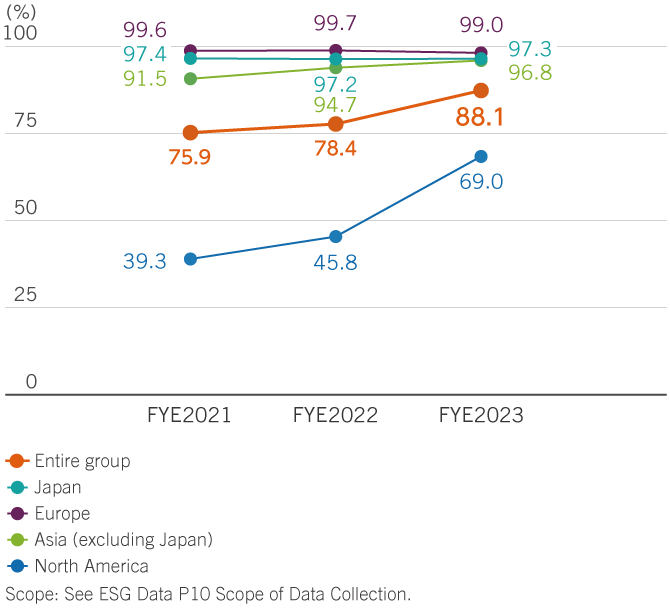

Waste recycling rates from business sites

LIXIL is committed to using resources efficiently by decreasing waste in production processes and improving our recycling rate. We have set a target of increasing the recycling rate of waste generated from our business sites to 90% globally by FYE2026.

Waste Reduction and Recycling at Production Sites

We are improving manufacturing processes at production sites to reduce raw material use and waste, and promoting the recycling of any waste that is generated. In FYE2023, we began recycling the gypsum molds used to manufacture sanitaryware at our Aguascalientes plant in Mexico, raising the overall recycling rate from 49.6% in the previous year to 84.0%. We also began recycling other materials including sludge at our Santa Clara plant in Mexico, raising the overall recycling rate from 16.6% in the previous year to 54.9%.

Since FYE2022, the LIXIL Housing Technology (LHT) plant in Vietnam has been making efforts to reduce the amount of sludge produced, and aims to recycle all of it into new raw materials within the plant. They have made preparations for the system, including obtaining detoxification certification for the materials to be recycled, and in FYE2023 vastly improved their recycling rate to 93.5% from 63.3% in FYE2022.

Having obtained certification as a biomass business operator and lobbied timber suppliers to join forest certification organizations, our Nabari Plant in Mie, Japan, succeeded in selling its previously discarded wood shavings as biomass fuel and reducing its wood shavings waste to zero in April 2020.

Our Value Chain

LIXIL is promoting the use of recycled materials such as recycled aluminum, recycled resin, and recycled wood in order to increase the ratio of recycled and renewable materials used for our products to minimize the use of new resources. We have set a target to increase the ratio of recycled aluminum used in our housing business to 100% by FYE2031. We are also working to reduce single-use plastic packaging, expand our supply of resource-efficient products designed for durability and reuse, and create a circular system that encourages product-to-product recycling.

Minimizing Use of New Resources

LIXIL factories in Japan are reducing the energy required to produce new ingots and other aluminum products by reusing aluminum scraps from outside their manufacturing process.

At LIXIL International water faucet factories, we also carry out alloy smelting in in-house furnaces. Up to 80% of the brass we use in these plants for the GROHE brand is recycled material collected in and outside the factories. For resin used in windows, we are aiming for circular material recycling and promoting the effective use and recycling of resin materials by creating a recycling system and installing sorting facilities for excess materials produced in plants.

Feeding raw materials into the aluminum smelter

• PremiAL low-carbon aluminum profile series

LIXIL has been developing aluminum recycling technologies for many years, and has achieved one of the highest recycling rates in the industry. In FYE2023, we launched the 70% recycled aluminum PremiAL R70 starting with profiles for buildings. Compared to products utilizing new ingots, the product helps reduce CO2 emissions by around 55%, and has received third-party EcoLeaf certification. In FYE2024, we plan to start selling PremiAL R100 made from 100% recycled aluminum.

• Artificial wood decking

LIXIL artificial wood decking has an environmentally friendly design and is made with 100% recycled materials. The boards are made using wood dust and shavings generated in manufacturing processes along with recycled plastic recovered by local governments.

Products made with recycled resources (Japanese only, a new page will open) >

Deck DC

• Reducing single-use plastic packaging

LIXIL is working to reduce the amount of plastic packaging that is disposed of by end users, and is transitioning to environmentally friendly alternatives. GROHE has been making the switch from plastic to sustainable alternative materials for product packaging since 2018 with their Less Plastic Initiative, and completely eliminated plastic from packaging materials in FYE2023. In Japan, the instruction manuals for kitchen and bathroom products purchased by end users now come packaged in bioplastic that is marine biodegradable.

Expanding Our Supply of Resource-Efficient Products

• Cradle to Cradle Certified® products (GROHE brand)

Four products have been certified Gold for satisfying the five Cradle to Cradle international criteria: material health, material reutilization, renewable energy & carbon management, water stewardship, and social fairness. With waste recycling rates of 99% and a use of brass with recycling proportions of up to 80%, LIXIL’s GROHE brand has incrementally approached a circular economy for years.

GROHE’s Cradle to Cradle Certified® products (A new page will open) >

Cradle to Cradle Certified® products

• Replaceable spout with built-in water purifier

Some LIXIL kitchen faucets are designed so that just the spout portion can be replaced with one that has a built-in water purifier. This helps reduce waste when the faucet reaches end-of-life.

Can upgrade to faucet with water purifier

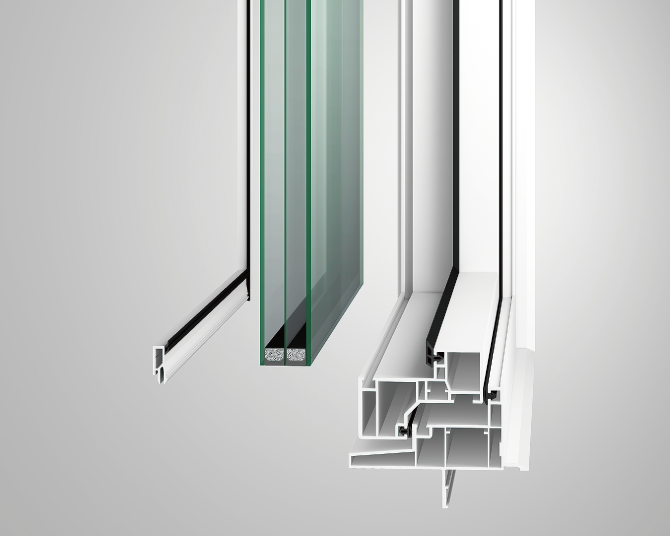

• Resin window EW (TOSTEM brand)

It achieves world-leading thermal insulation by using resin materials, which don’t conduct much heat, separating the space in the resin frame to create a multilayered hollow structure that suppresses heat transfer, and using high-performance triple-glazed glass. The windows feature a push-edge adhesive-free specification that enables easy separation and collection of the resin frame and glass, and in addition to the frame itself, we also use recyclable resin for the surface layer of the frame.

Products made with recycled resources (Japanese only, a new page will open) >

EW cross section that enables easy separation and collection of the resin frame and glass

• withCUBE mobile bathroom booth

It does not require any large-scale construction, so it can be installed in as a little as one day* and easily withdrawn, thus making it easier to provide toilet facilities at distribution centers and other locations. It can help reduce the amount of resources and energy used and the amount of waste generated across a product life cycle by providing toilet spaces that can be easily installed in and removed from various different locations through rental and lease agreements.

* Preparatory construction to install water and wastewater lines and electrical wiring may be required separately.

withCUBE

Creating a Circular Product-to-Product Recycling System

So that products at the end of their life can be again turned into the same product, we are striving to help realize a circular economy by building an eco-system from procurement to production, sales, construction, and recovery while teaming up with stakeholders such as governments, municipalities, industry associations, and business partners.

Expanding Our Impact

LIXIL is working to develop circular materials that promote the effective use of waste plastic to reduce the amount of waste plastic that is difficult to recycle.

• revia, a new recyclable material

We developed revia, a new recyclable material made from a combination of waste wood from the demolition and repair of buildings and nearly all kinds of waste plastic, including composite plastics that have been difficult to recycle up until now and consequently incinerated or placed in landfill. Recycling plastics that would otherwise be incinerated also contributes to reducing CO2 emissions. In FYE2023, we launched revia pave as our first revia product.

revia

revia pave