LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

Updated: October 19, 2021.

Today, the natural resource crises are forecasted to become one of the top five critical existential threats to the world in the next five to ten years ¹, and like many environmental problems, the issue is intertwined with others. Mass production and consumption factors into global greenhouse gas emissions ², of which 45% come from industry, agriculture and land use. Transitioning to renewable energy is vital if we are to tackle climate change, however it would only address 55% of global greenhouse gas emissions. The landfills where industrial wastes end up result in pollution of groundwater, and issues such as microplastics continue to impact water security and sea-life, globally.

In aim to mitigate the environmental impact of our generation, the realization of a Circular Economy is considered a pressing need for all global citizens, and businesses are innovating sustainable models throughout their supply and value chains.

Building Better Homes Through Circularity

The growing global population comes with increased demands in housing; and rapid urbanization in the modern age has resulted in overmining of raw materials used in building and construction that accounts to 40 percent of global resource consumption ³. As a maker of pioneering water and housing products, LIXIL defines Water Conservation and Environmental Sustainability as one of three focuses in its Corporate Responsibility strategy and LIXIL Environmental Vision 2050 “Zero Carbon and Circular Living.” This shared vision aims to reduce CO₂ emissions from its business processes, products, and services to net zero by 2050, and to become a leader in the field of conserving water and limited resources for future generations. LIXIL plays an important part in conserving the environment’s resources.

Mindful of the shift to sustainability and circularity, responsible use of resources is incorporated into the design of LIXIL’s products and services, using recycled materials where possible, and designing of products with long life spans and recyclability in mind. As a proponent of sustainable living, LIXIL offers products with parts that can be replaced or upgraded, expanding its range of product-as-a-service options, while minimizing environmental footprint for consumers in the user phase.

Revolutionizing Product Design: GROHE’s first Cradle to Cradle certified® products

Spearheading LIXIL’s recent innovations on circularity GROHE has taken an incremental approach towards circularity over the years, accomplishing a recycling rate of 99 percent with brass with recycling proportions of up to 80 percent. In its latest step towards circular value creation the brand launched four of their best-selling products as Cradle to Cradle Certified®(C2C) variants. C2C products are assessed for their use of environmentally safe, healthy, and recyclable materials. To achieve C2C certification, a product is evaluated across five categories: material health, material reutilization, renewable energy, water stewardship, and social fairness. Each product is then designated a level of achievement (Basic, Bronze, Silver, Gold, or Platinum).

Together with its partners, GROHE implemented the revolutionary C2C design concept, that aims to manufacture products that can be used to make new products at the end of their life cycle in the future, contributing to the drastic reduction in the use of new resources. Designing intelligent products, processes and systems that takes the entire life cycle of products into account, resources can potentially be re-used endlessly, extending far beyond conventional recycling.

Four GROHE products achieved Cradle to Cradle Certified® at the Gold level

GROHE achieved a Gold level C2C certification by the Cradle to Cradle Products Innovation Institute for its launch of four best-selling products as C2C-certified variants – three faucets (GROHE BauEdge S-Size, GROHE Eurosmart S-Size, GROHE Eurosmart Kitchen) and the GROHE Tempesta shower rail set. To add, the SilkMove ES (energy-saving) technology in GROHE BauEdge and GROHE Eurosmart prevents the unnecessary use of hot water that helps reduce the carbon footprint of buildings.

“Circularity is a long journey and we are at the very beginning”, explains Thomas Fuhr, Leader Fittings LIXIL International. “The certification process is extremely demanding – it considers upstream manufacturing processes as well as internal production – but the gains are clear: a drastic reduction in the consumption of new resources. It is our obligation to drive a mindset shift in the industry.”

GROHE is tackling the next challenge – working on processes to collect used C2C faucets.

Recycling Plastics in TOSTEM‘s “EW” Resin Windows

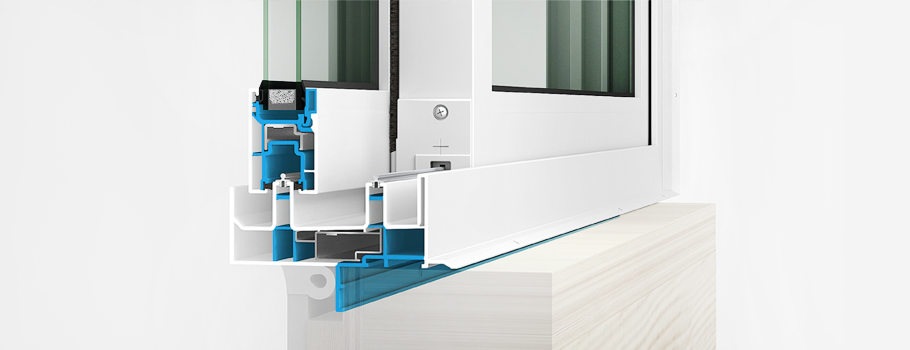

TOSTEM “EW” resin window

In Japan, the plastic used in synthetic resin windows mostly ends up in landfills rather than being recycled due to the complicated make-up of the materials. To address this issue, LIXIL partnered with Profine, a leading global producer of PVC profiles for windows and residential doors manufacturer known for their advanced plastic recycling technologies, to establish a process to re-use and upcycle these parts in the production of “EW” resin windows; in line with the LIXIL Plastics Action Statement which redefines how the company uses and promotes the circular use of plastic.

Launched in August 2021, the windows are made with three times the amount of recycled materials compared to conventional products. It also features a “push edge specification” that enables easy separation and collection of the resin frame and glass without using adhesives. Moving forward, LIXIL aims to partner with public and private sectors to establish a recycling system for resin windows.

The sectional illustration of EW – blue parts are made from recycled materials; both blue and white parts can be recycled after use

In addition to designing products, LIXIL is also developing hybrid materials that could potentially change the landscape for recycled plastics. While it is still in the testing stages, the new material is chiefly made of recycled wood and mixed plastic waste. Plastics that are mixed with other materials, such as marine plastics and confectionary bags that have long been considered difficult to recycle can also be utilized for this material, eliminating the complex process of sorting various plastics necessary for conventional recycling. This highly durable material is considered suitable for pavements and as decking materials used in the exterior of commercial facilities or office buildings, and could potentially serve as a solution to utilizing plastic waste around the world.

Satoru Yoshida, Executive Officer, Executive Vice President, LIXIL Housing Technology said, “At LIXIL, we are actively developing products toward the realization of a circular economy. By developing 100% recycled wood decks, actively using domestic lumber that can be used over and over as the base material in our flooring products, and most recently with EW, the responsible use of resources comes as a part of minimizing our environmental footprint in our processes, products and services. Through our expertise and innovations, we are contributing to a circular living - to make better homes a reality for everyone, everywhere.”

¹ World Economic Forum (link)

² Ellen MacArthur Foundation (link)

³ California Department of Resources Recycling and Recovery (link)

Learn more about the EW, and LIXIL’s commitment to circularity, and products here (video):

Our Stories

- Backing People and Passions to Drive Innovation

- How Toilets in Schools are Catalyzing Change in Communities

- Building the Future by Recycling the Past

- Reinventing Consumer Connections in the World's Largest E-commerce Market

- Tackling Household Water Inefficiency in a Water-Stressed World

- Plugging the Plumber Shortage

- Pioneering Solutions to a Sewage Crisis in Rural Alabama

- Meet the Citizen Developers Changing How We Work

- Design and Brand Identity Transformation at LIXIL

- Three Changes to Prepare Europe’s Sanitary Industry for Growth

- Three Steps to Creating an Inclusive Culture

- From Linear to Circular: Giving Products in Your Home a New Lease of Life

- Crafting Unique Experiences as well as Products

- GROHE X: A Digital Brand Experience

- Design-led Innovation Delivering True Value

- Responsible Use of Plastics

- Empowering our People for an Agile Future

- Turning the Waves of Change into Opportunities

- SATO Tap: a New Handwashing Solution for All

- New Ways of Working Take Flight at LIXIL

- INAX: Rituals of Water

- Refreshing our sanitation targets, standing firm on our commitments

- Developing Attractive and Differentiated Products

- Conserving Water: The New Normal

- Insulating For a Warmer and Healthier Home

- Open Kitchen, Open Communication

- Tackling Open Defecation in India

- Shaping the Future of Faucets, One 3D Layer at a Time

- Bathed in Culture and Tradition

- Remodeling the Housing Market

- LIXIL's AQUA CERAMIC makes bathroom stains a thing of the past

- The Technology of Water

- Tackling Challenges in Global Sanitation and Hygiene