LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

Updated: January 15, 2021.

Did you know the history of plastics dates back to the early 1900s? Following the creation of the most versatile kind of synthetic material, it was quickly adopted around the world, making more items accessible and affordable for many.

Yet in the last 50 years, the mass production of plastics worldwide has increased twentyfold while we consume a staggering 381 million tons of plastic annually¹. Mankind’s dependency on this economic material for over a century has come at a steep price. Only 10 percent of plastics are recycled while the remaining 90 percent could take hundreds of years to decompose.

As businesses and individuals, it is up to us to responsibly use resources such as plastic. LIXIL is no exception.

A Comprehensive Approach

GROHE Blue offers still, medium or sparkling water directly from the kitchen tap

In 2020, LIXIL’s GROHE brand received multiple reputable awards recognizing the efficient use of raw materials in both the production and product use phases: The Sustainability Heroes Award 2020, German Sustainability Award 2021, and The German Sustainability Design Award 2021. But the iconic brand has a longer history in implementing sustainability, spearheading LIXIL’s bold and comprehensive approach to water conservation and environmental sustainability. The Less Plastics Initiative launched in 2018 has helped reduce an estimated 23.5 million items of plastic packaging; by 2021, and is targeting 35 million items.

“We were able to collect new and better ideas through workshops we arranged in our production plants,” says Stephan Thater, Central Industrial Engineering, Corporate Packaging. He is convinced that involving more employees has been pivotal to their success in designing new and more efficient packaging. The project itself was carried out in several phases: after identifying the most commonly used types of plastic packaging, they began researching new and more sustainable alternatives before running a number of tests. The final packaging was then implemented. “In order to uphold sustainability, I believe it is important that we continually review our processes, especially by listening to the voices of our employees,” he notes.

The Less Plastic Initiative has also been extended to products. GROHE Blue is a water filtration system that offers still, medium or sparkling water directly from one’s kitchen tap – chilled to the optimum drinking temperature for a perfect taste. The product enables every consumer to save up to 200 plastic bottles per person in a year.²

Thomas Fuhr giving a speech at digital award ceremony held in Dusseldorf

(December 4th, 2020)

Recognized for its potential to change the way water is consumed, GROHE Blue received the German Sustainability Award 2021 DESIGN. Contributions to the environment throughout the entire value chain, including helping consumers to live more sustainably, also won GROHE the German Sustainability Award, in the transformation field “Resources.”

“These awards are a milestone for us – one that we could reach as a team. We have a responsibility toward future generations and, therefore, also toward the environment. That is exactly why we want to continuously introduce new ideas in the area of sustainability, which will make responsible use of resources possible,“ says Thomas Fuhr, Leader Fittings LIXIL International.

Changing The Industry Through Innovation

Prototypes of biomass plastic material derived from microorganisms

“It’s important to be conscious of what we do every day, like making it a habit to carry tote-bags when we shop. As a researcher, though, I wanted to take on the challenge of developing materials that lead to a fundamental solution,” says Sayaka Hotate, a member of the Analysis and Material Research Laboratory, Environmental Material Group, LIXIL. Hotate’s team has been responsible for conducting research on utilizing biomass plastics derived from microorganisms.

While conventional plastics are made from petroleum, biomass plastics are made from renewable biological resources. Among them, a new material developed by LIXIL is a non-biodegradable biomass plastic which uses an ingredient called “paramylon,” derived from Euglena. Since it is a non-edible material, it has no impact on food security, shares the malleable characteristics of existing synthetic plastics, while its solidity and resistance can be controlled for practical use.

Jun Tanaka, another key member of the Analysis and Material Research Laboratory, Environmental Material Group at LIXIL added, ”Chemical manufacturers research highly versatile materials to meet the product needs of many industries, but for LIXIL to be able to use materials that meet specific requirements, we had to lead the research. If the materials we develop reach industry standards, LIXIL can increase its competitiveness.”

While the newly developed material has the potential to be used in a wide variety of products, there is further testing required to commercialize. LIXIL’s plan is to use this new material globally, across brands and business units in the future.

Design-Driven Approach to Minimize Environmental Impact

INAX’s Aqua Power Showerhead packaging made from paper

“Until now, using plastic packaging made sense because it protected products from the high humidity in Asian markets, where many of LIXIL’s products are sold in street shops. But as seen in India, Thailand and Vietnam, governments in Asia have started to reinforce regulations on single-use plastics,” says Yoichiro Tomioka, Product Designer, LIXIL, who designed the new packaging for INAX's Aqua Power Showerhead ahead of its global expansion.

“A designer's job is to create ‘products’ and ‘experiences’ that consumers desire. Today, environmental sustainability has become a major concern for end-users. As part of ensuring that we are using materials responsibly, we decided to reconsider the use of single-use plastics in our packaging. INAX is a brand that encourages people to “LIVE WELL,” so the responsible use of plastics is also consistent with what our brand promise.”

By applying a thin plastic film to the surface of the paper packaging, Tomioka was able to ensure durability, while minimizing plastic use. “We will continue to build on this success and work with others within the company to experiment by applying what we have learned, but also explore the use of alternative materials to a wider range of products around the world.”

Changing Employee Behavior

While teams and projects have made progress within their own scopes of responsibility, LIXIL is now looking to redefine the use of plastics globally. In October 2020, LIXIL announced the LIXIL Plastics Action Statement, a commitment that serves as the basis for all business processes, products and services to reduce plastics across the world. LIXIL is reducing single-use plastics and promoting recycling further, propelling research and development of renewable materials, but also promoting the use of alternative materials.

As part of its annual“LIXIL Community Day” held in October 2020, LIXIL joined the “mymizu” (My Water) challenge in cooperation with the NPO Social Innovation Japan. Approximately 2,500 employees participated in this project by refilling their reusable water bottles at free refill spots and recording the number of times they did so in the mymizu app. Employees were able to save more than 34,000 of PET bottles by taking part in this project ³.

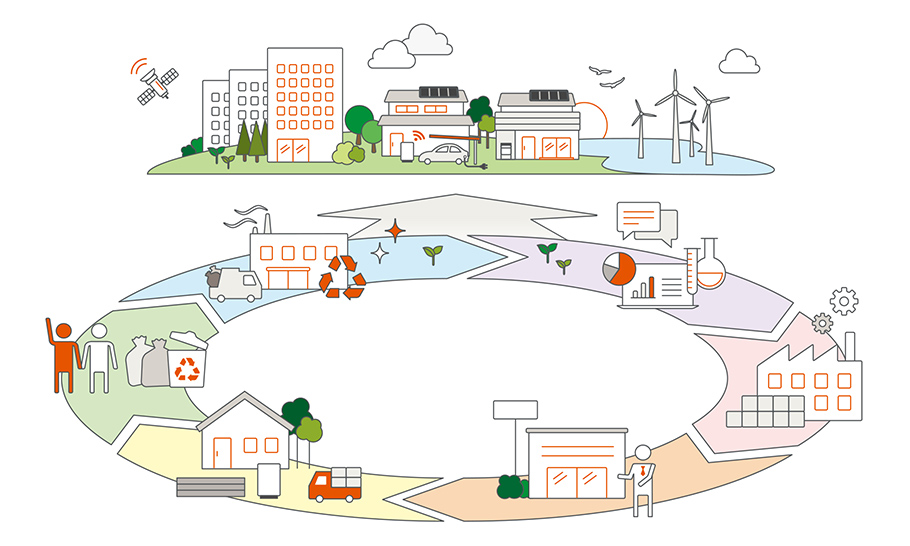

“As a global maker of water and housing products, we are taking an all-encompassing approach to contribute to the realization of a circular economy. The Plastics Action Statement outlines our direction forward in order to achieve our Environmental Vision 2050. We want to encourage our employees to promote new ideas, and welcome creativity in all of their capacities, whether it be as simple as using cups instead of plastic bottles during team meetings or developing new business models that would extend product life. It is what drives innovation, pushing LIXIL’s competitiveness,” commented Toshihiro Kawakami, Leader of Environment.

Our Stories

- Backing People and Passions to Drive Innovation

- How Toilets in Schools are Catalyzing Change in Communities

- Building the Future by Recycling the Past

- Reinventing Consumer Connections in the World's Largest E-commerce Market

- Tackling Household Water Inefficiency in a Water-Stressed World

- Plugging the Plumber Shortage

- Pioneering Solutions to a Sewage Crisis in Rural Alabama

- Meet the Citizen Developers Changing How We Work

- Design and Brand Identity Transformation at LIXIL

- Three Changes to Prepare Europe’s Sanitary Industry for Growth

- Three Steps to Creating an Inclusive Culture

- From Linear to Circular: Giving Products in Your Home a New Lease of Life

- Crafting Unique Experiences as well as Products

- GROHE X: A Digital Brand Experience

- Design-led Innovation Delivering True Value

- Responsible Use of Plastics

- Empowering our People for an Agile Future

- Turning the Waves of Change into Opportunities

- SATO Tap: a New Handwashing Solution for All

- New Ways of Working Take Flight at LIXIL

- INAX: Rituals of Water

- Refreshing our sanitation targets, standing firm on our commitments

- Developing Attractive and Differentiated Products

- Conserving Water: The New Normal

- Insulating For a Warmer and Healthier Home

- Open Kitchen, Open Communication

- Tackling Open Defecation in India

- Shaping the Future of Faucets, One 3D Layer at a Time

- Bathed in Culture and Tradition

- Remodeling the Housing Market

- LIXIL's AQUA CERAMIC makes bathroom stains a thing of the past

- The Technology of Water

- Tackling Challenges in Global Sanitation and Hygiene