LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

- CONTENTS

-

- Our Approach

- Our System

- Enhancing Quality across Product Lifecycle

- Stage Gate System

- Culture That Strives for Superior Quality

- Responding to Serious Product-Related Accidents

- Long-Term Guarantee to Facilitate Long, Safe Customer Use

- Offering Information on How to Use Products Safely

- External Awareness-Building Activities

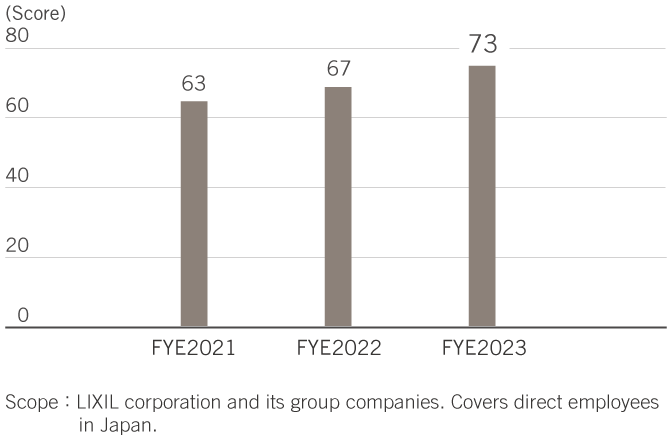

Progress in FYE2023

- Quality awareness survey overall positive response score

- 73

Our Approach

LIXIL firmly believes that quality is the key to earning the trust of our customers and society. We have stipulated improving the quality and safety of our products as one of our material issues. We have published the LIXIL Quality Principles in 14 languages to ensure the continuous pursuit of highest-quality manufacturing and services in various countries around the world. Serious product-related problems make customers anxious and adversely affect our reputation. That is why we pursue product quality management initiatives such as confirming legislative compliance based on the LIXIL Product Safety Principles.

LIXIL Quality Principles (A new page will open) PDF: 40KB >

LIXIL Product Safety Principles (A new page will open) PDF: 40KB >

Our System

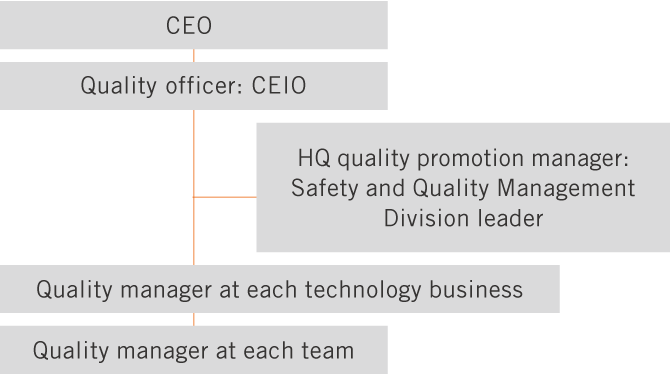

LIXIL works to develop robust company-wide quality management systems and resolve any quality-related issues at the initiative of our Safety and Quality Management Division overseen by the Chief Environmental Impact Officer (CEIO), who reports directly to the CEO. LIXIL International oversees product quality outside Japan, with product-specific Chief Operations Officers (COOs) managing product quality directly.

The company-wide quality management conference, which conducts quarterly management reviews, has been working to strengthen quality control.

Quality management system

Enhancing Quality across Product Lifecycle

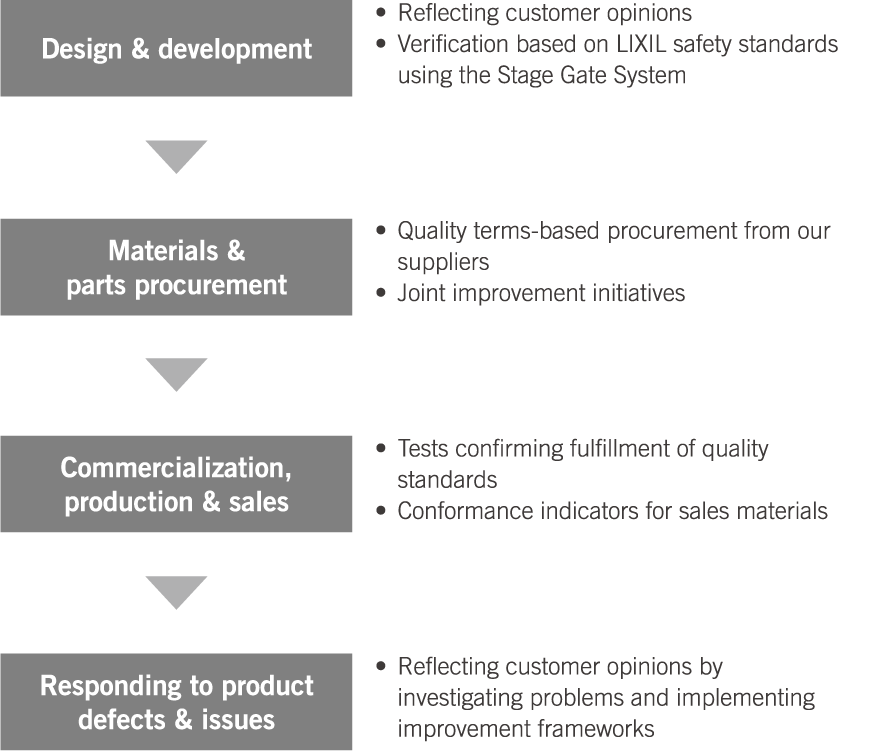

To ensure customer safety, LIXIL is focused on enhancing quality across the full lifecycle of all products, from development through to design, procurement, manufacturing, distribution, and after-sales support.

1) Design and Development

During the development stage, we introduce risk assessment methodologies such as fault tree analysis (FTA), failure mode and effect analysis (FMEA), and design review based on failure mode (DRBFM), which are used globally to assess risks that may arise when using products.

Furthermore, in addition to customer comfort and ease of maintenance, we promote product design and development that achieves both environmental consciousness and universal design that is easy for everyone to use. We are also seeking to ensure accurate recognition of and compliance with local and international laws and regulations as we continue to pursue collaborative development projects globally.

Environmentally Conscious Design >

Promoting Universal Design >

2) Materials & Parts Procurement

We set quality standards to which our business partners must adhere. We also design joint activity themes to help resolve quality-related issues whenever necessary.

3) Commercialization, Production & Sales

We only commercialize products that have passed rigorous stress tests and quality checks for durability, weather resistance, and other properties. Products that require specific labeling to indicate conformance with safety and quality standards are clearly marked in our catalogues and other sales materials as meeting required criteria.

We also strive to provide better, readily understandable product explanations, including experience-based showroom displays and online videos, to ensure that customers select appropriate products.

4) Responding to Product Defects & Issues

We have a system in place for incorporating customer opinions with regard to product-related accidents and defects. We thoroughly investigate the cause of any problem via the system and implement improvements, not only in product design, but across all processes from manufacturing to distribution. To prevent product defects and problems, we consistently work to advance organizational management to ensure improvement measures are fully integrated, and to develop governance frameworks to promote better management.

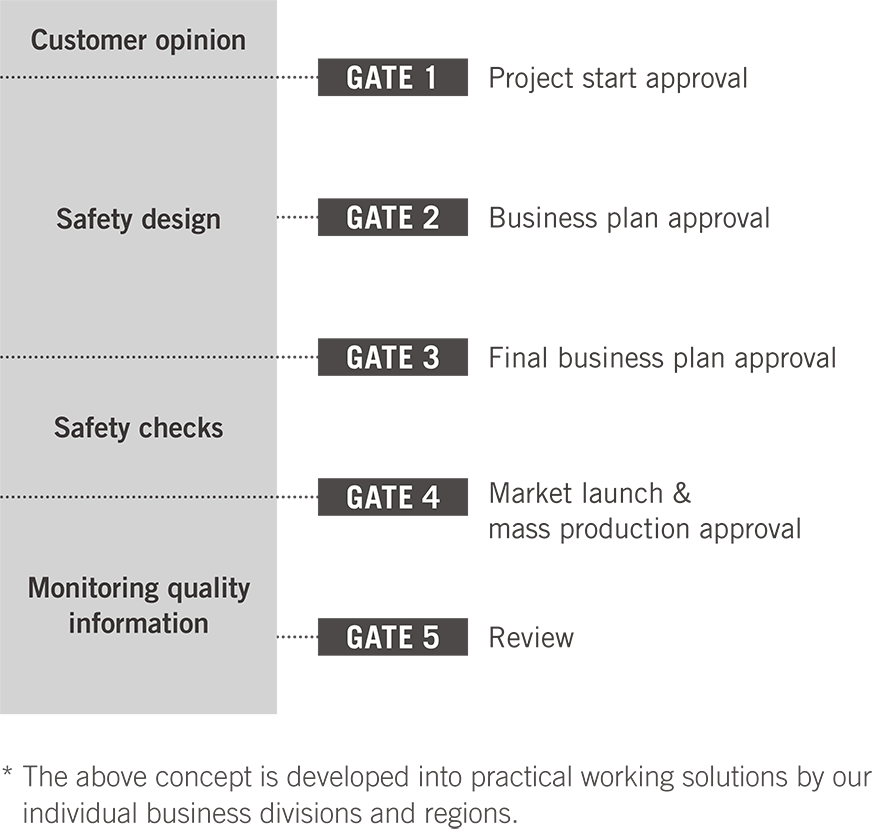

Stage Gate System

In product development, LIXIL categorizes the various processes from research and development to commercialization and merchandising into “stages” and places “gates” between transitions to subsequent stages. Under this system, we ensure evaluations are carried out and management decisions are made properly. To raise the level of completion in design, quality, and production, the development, manufacturing, and sales departments collaborate with each other at each stage of the development process. The criteria for gate evaluation are also re-examined on an ongoing basis to promote the development of even higher-quality products.

Concept of Stage Gate System

Nurturing a Culture That Strives for Superior Quality Product Manufacturing and Services

LIXIL works to build a culture that focuses on enhancing quality through training, awareness-raising activities, and knowledge sharing. We measure the level of awareness of quality via a survey of all employees in Japan and work to generate further improvements.

Quality Control and Product Safety Education

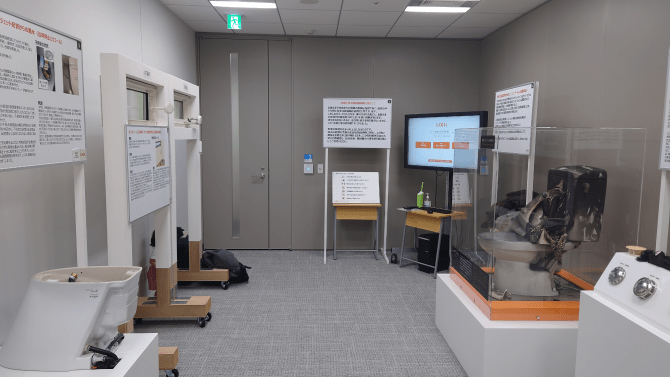

LIXIL has set up a quality education system to provide training on enhancing quality and ensuring product safety. In FYE2023, we conducted training sessions on managing quality and preventing product-related accidents for approximately 500 employees at management level in order to raise awareness of quality further among our company leaders. For a more expanded group of 1,400 employees, we also conducted e-learning on case studies, quality regulations, and quality management systems. As part of these training activities, we use examples of past quality defects and product-related accidents along with the actual products and descriptions of background factors to promote understanding of the fundamental cause of product safety issues.

Our archive with displays on past quality issues and product incidents

We also provide product safety education for new employees, and offer educational opportunities for employees whose work requires expertise on how to observe Japan’s Electrical Appliances and Materials Safety Act, Building Standards Act, and other relevant laws.

We strive to prevent quality defects and accidents from happening or reoccurring by identifying risks that can cause defects and accidents across the company, strengthening employee awareness, and ultimately encouraging activities that secure cross-sectional improvements.

Promoting Internal Awareness through Information-Sharing and Forums

We use inhouse social media platforms to post quality policies, CEO messages, and case studies as part of our awareness-raising activities. In FYE2021, we created the LIXIL Quality Journal to help consistently raise employee awareness on quality topics. The journal highlights initiatives and stories of departments that have used their mistakes to make further more quality improvements.

Our Product Quality Forum held each November rewards outstanding improvement-focused activities chosen from among LIXIL group companies worldwide. Thanks to the consistent conveying of information and other awareness-raising activities, we have seen an increase in recent years in customer-oriented improvement activities that focus more earnestly on customer needs. In FYE2023, the forum was conducted online for a worldwide audience and attracted approximately 7,000 viewers.

All-Employee Awareness Survey and Action Plan

We conduct quality awareness surveys of all employees in Japan in order to raise awareness of product quality and promote quality-enhancing initiatives. Based on the survey results, we then formulate action plans for each department that include capital investments designed to improve quality. Thanks to progress made in each department, the overall survey score has improved for the third consecutive year.

In FYE2023, we also added a write-in response option to questions that had low scores in previous years, then analyzed the primary causes and shared the findings. We additionally interviewed departments whose overall scores had improved, and published positive examples in the LIXIL Quality Journal.

Quality awareness survey overall positive response score

Sharing Knowledge within the Company to Raise Quality Level

LIXIL Water Technology (LWT) Japan created a database of past cases of quality issues and solutions, and used it to conduct training within the sales department in January 2023. We expect that these efforts will make it easier for the customer service center to provide appropriate first response and resolve issues quickly. LIXIL Housing Technology (LHT) has also set up a trial hotline for sales representatives and other staff who have questions about quality issues. By sharing knowledge and experience across departments, we aim to raise the level of quality throughout the organization.

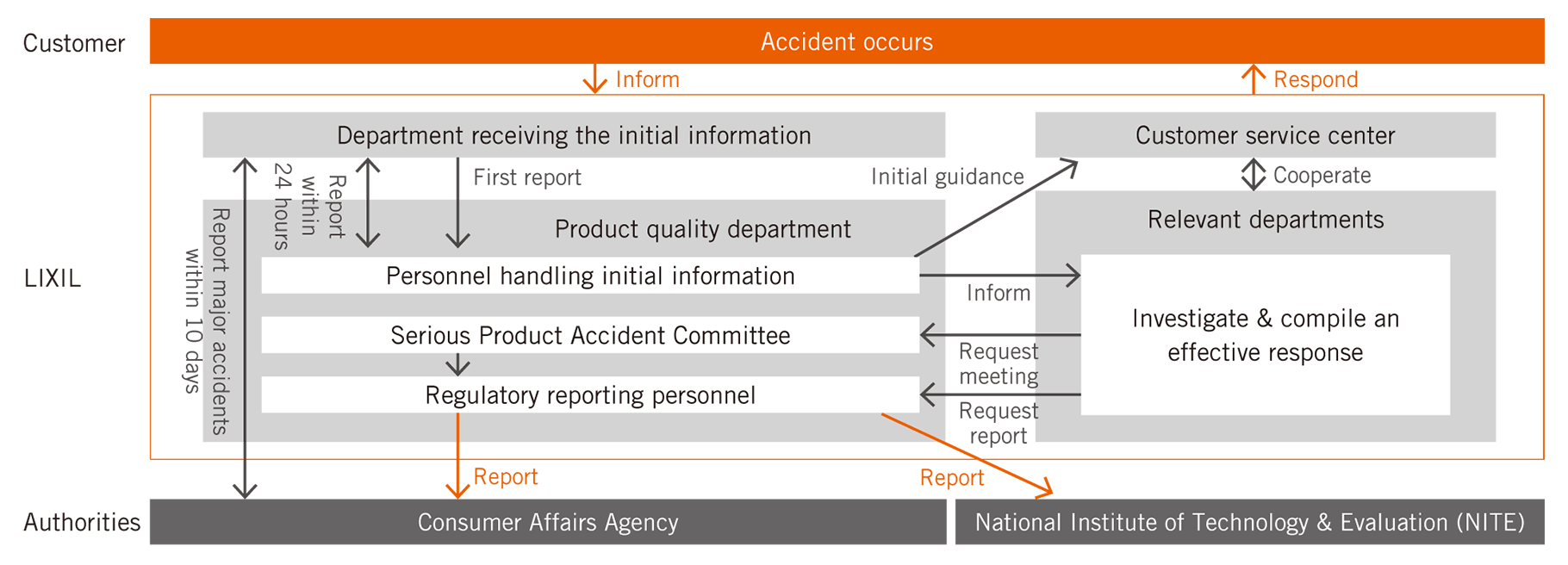

Responding to Serious Product-Related Accidents

At LIXIL in Japan, whenever a product-related accident occurs, the product quality department collects information within 24 hours of receiving notification, and sends an emergency notice to relevant departments. If an accident that could have a serious consequence occurs, a department receiving the initial information reports it directly to senior management to ensure a swift response. The department also cooperates with other departments to formulate on-site responses and thoroughly investigate accidents. We submit a report to relevant government authorities within 10 days of an accident occurring as stipulated in Japan’s Consumer Product Safety Act. We also seek to prevent a recurrence by reflecting any lessons learned from accidents in product design, and proactively developing technologies that help ensure accident prevention and safety. Regarding suspected legal infringements, our technology or other relevant departments will ascertain if an infringement has actually occurred, and submit a report to the authorities concerned. We follow a similar process for suspected legal infringements as we do for product-related accidents, namely, we conduct a thorough investigation of the cause and implement appropriate countermeasures to prevent a recurrence.

Number of Legal Infringements and Significant Product-Related Accidents

| FYE2021 | FYE2022 | FYE2023 | |

|---|---|---|---|

| Number of legal infringements | 0 | 0 | 1 |

| Number of serious product-related accidents | 2 | 6 | 6 |

* A violation of laws and regulations occurred in FYE2023 when the LED lighting (third-party product) mounted on LIXIL’s three-sided mirror failed to display the PSE mark stipulated in Japan’s Electrical Appliance and Material Safety Act. In that case, the third-party product was independently arranged by sales representatives, so we reinforced the fact that purchasing products without involving the pertinent business division is strictly prohibited, and conducted training on the Electrical Appliance and Material Safety Act for our sales divisions. We also reviewed the purchasing process at the sales department to prevent the recurrence of the similar incidents.

Emergency Procedure for Responding to Accidents

Long-Term Guarantee to Facilitate Long, Safe Customer Use

Today, houses are designed to last much longer than in the past. In recognition of these changing trends, we offer a maximum 10-year LIXIL Long-term Guarantee Service that enables customers to use products safely over a longer period of time.

Offering Information on How to Use Products Safely

We publish product-specific instructions for all major products on the website to ensure safe product use, along with videos illustrating how to look after and clean products to ensure appropriate use.

In FYE2023 we used the LIXIL Owners Club email magazine to reach an even wider group of customers with news on product recalls and servicing in efforts to prevent accidents before they happen.

Product manuals (Japanese only, a new page will open) >

How-to videos (Japanese only, a new page will open) >

External Awareness-Building Activities

Safety Education Program: Think about Safety in the Home

As part of our product safety-related activities, we have developed safety educational materials in cooperation with NPO the Association of Corporation and Education (ACE) for elementary school students, and provided these materials free of charge to educators. The materials encourage children to learn about hidden dangers in the home, such as stumbling on the stairs or accidents in the bathroom, and to think about and implement ways to prevent accidents.

- Outreach classes and participants

- 225times

6,700students

We also conducted outreach classes on the theme “Think about Safety in the Home,” which attracted roughly 6,700 students over a total of 225 sessions. Seeing that participants included students from early elementary school grades, in FYE2023 we created animated learning materials. The materials won an Award of Excellence at the Commendation on Instructional Materials for Consumer Education in 2022 conducted by the National Institute on Consumer Education (NICE).

To provide equal opportunities for children living in less populated areas, we worked together with the association Professionals for All Schools to develop new online learning materials that were used to conduct a total of five lessons for 66 students. NICE also honored these materials with an Award of Excellence in 2023.

Safety Education Program (Japanese only, a new page will open) >

LIXIL’s Outreach Classes >

Outreach Classes

Online lessons

Raising Consumer Safety Awareness

We help consumers think of ways to prevent accidents at home by giving lectures at product safety seminars hosted by the National Federation of Regional Women’s Organizations and other consumer organizations, covering topics such as accidents in the toilet or bathroom or tripping over steps or falling down. We have given 80 such lectures to approximately 8,600 people to date.

In FYE2023, we held 14 sessions and attracted 1,200 participants while always observing COVID-19 safety protocols, such as restrictions on attendee numbers.

- Seminar sessions and participants

- 80 times

8,600people

Product safety seminar