LIXIL makes pioneering water and housing products that solve everyday, real-life challenges, making better homes a reality for everyone, everywhere.

- Global Site

-

- English

- Japanese

- Brand Sites

Global

- Global Site

-

- English

- Japanese

- Brand Sites

Progress in FYE2023

- Lost time injuries frequency rate (LTIFR)

- 0.46

- Number of work-related fatalities

- 0

Our Approach

LIXIL positions prioritizing the safety of all employees as one of our material issues. In accordance with our company-wide LIXIL Occupational Health and Safety Principles approved by our executive officers, we are pursuing zero work-related accidents by introducing an occupational health and safety management system and implementing a PDCA approach. In compliance with the Industrial Safety and Health Act in Japan, LIXIL has established a Health and Safety Committee for each business base, where we share and discuss occupational health and safety issues in labor-management consultation. This approach plays a key role in fostering a corporate culture where we always act with a "safety first" mindset.

LIXIL Occupational Health and Safety Principles (A new page will open) PDF:49KB >

Our System

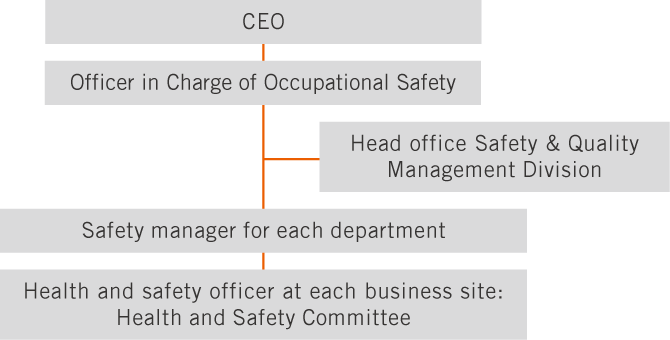

Occupational safety management structure

Our occupational health and safety management system is based on the Occupational Health and Safety Assessment Series (OHSAS) and ISO, and involves implementing company-wide principles and core rules. GROHE AG in EMENA region is also certified to ISO 45001. We conduct management reviews of each technology business, and each function reports their activities to management on a monthly basis and ensures advice and instructions are implemented for continuous improvement. We also conduct internal audits of each business base every year.

In FYE2022, we renewed our safety management structure in order to strengthen governance relating to occupational safety. In addition to our ongoing initiatives, from FYE2023 onward, we have started conducting company-wide management reviews by the officer in charge of occupational safety and audits by our headquarters Safety Management Department twice a year. The officer in charge of occupational safety also announces medium-term and fiscal year occupational safety targets, and each function in the technology businesses determines and implements targets and action plans that align with the broader company-wide objectives. The officer in charge of occupational safety reports to the Board of Directors at least once a year on progress toward targets, audit results, and other key updates relating to occupational safety risk. We also seek to make continuous improvements by holding Health and Safety Committee meetings for each business base where the company and employees come together to share and discuss occupational health and safety issues.

Furthermore, we hold meetings with LIXIL International safety managers to exchange information on safety activities being conducted at each base.

Efforts to Eradicate Occupational Accidents

In order to prevent work-related accidents, LIXIL seeks to promote the universal implementation of measures compiled as a result of past accidents, and to create systems that enable each one of managers and other employees to predict danger and take preventive action.

Safety Meetings

In each technology business, we gather all the safety officers together from each business base for safety meetings twice a year to share and discuss safety policies and priority measures.

Departments those who promote occupational safety at each technology business also conduct annual audits to assess legal compliance and management systems at all business bases under their control. In FYE2023, we conducted audits at 73 bases in Japan. We implement countermeasures at each business base based on the results of the audits and also obtain a good understanding of effective safety activities that we then share more widely on the intranet.

Universal Implementation of Accident Countermeasures

Departments in charge of promoting occupational safety of the headquarters and each technology business verify the effectiveness of measures implemented at the sites where any incidents have occurred. We are also strengthening our efforts to inspect any similar risks at other bases and deploy universal countermeasures at all business bases. Regarding particularly high-risk incidents, we also monitor progress on the implementation of countermeasures at each business base to prevent similar incidents from reoccurring in the future.

Safety Education

We provide safety education to a wide range of employees, from new hires to newly appointed plant leaders. In FYE2023, we determined essential safety management skills for 1,458 team leaders* in our plants, assessed their skill levels and provided training to improve their skills. LIXIL has set up a safety education program "Anzen Dojo" in Japan where visitors can simulate past occupational accidents. LIXIL Water Technology (LWT) Japan’s major facility Tokoname Anzen Dojo was refurbished and reopened in September 2022. In FYE2023, we held 51 training sessions for a total of 527 participants. So far, Anzen Dojo training was held more than 550 times for over 5,000 people.

* Team leaders: Each manufacturing process at LIXIL is divided into teams and the team leader is responsible for coordinating their team.

Number of Safety Training Sessions and Number of Participants

| FYE2021 | FYE2022 | FYE2023 | |

|---|---|---|---|

| Number of sessions | 3 | 42 | 51 |

| Number of participants | 52 | 381 | 527 |

* From FYE2022, we have changed the calculation criteria to include the number of risk simulation training sessions for new employees and the number of participants in those sessions, and also recalculated the data for past years to reflect the same criteria.

Employees receiving a lecture at an Anzen Dojo

Practical employee learning session using actual equipment

Hazard Source Risk Assessment

LWT Japan conducts risk assessments of hazard sources relating to existing and new facilities and takes measures to prevent disasters from occurring. The assessments cover R&D base as well as factories.

Employees who conduct risk assessments in the R&D base

Our Response to Occupational Accidents

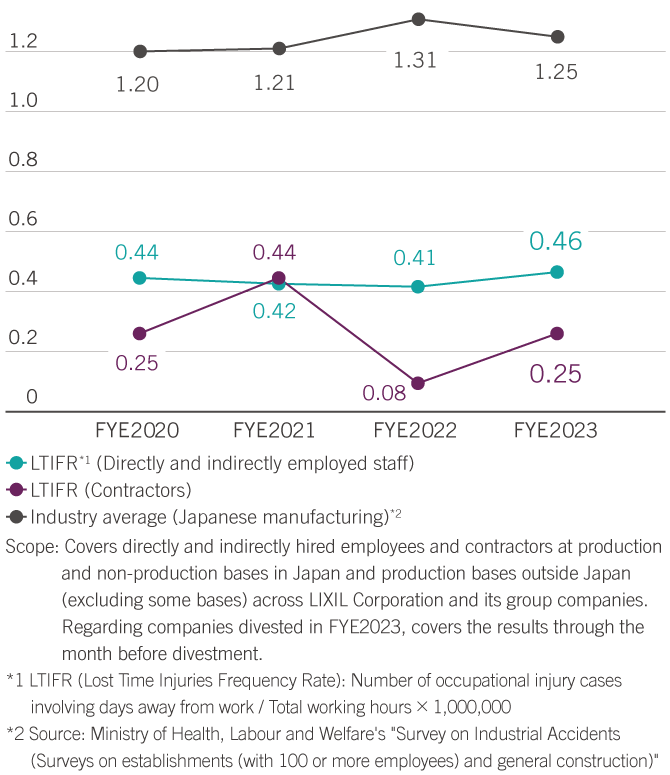

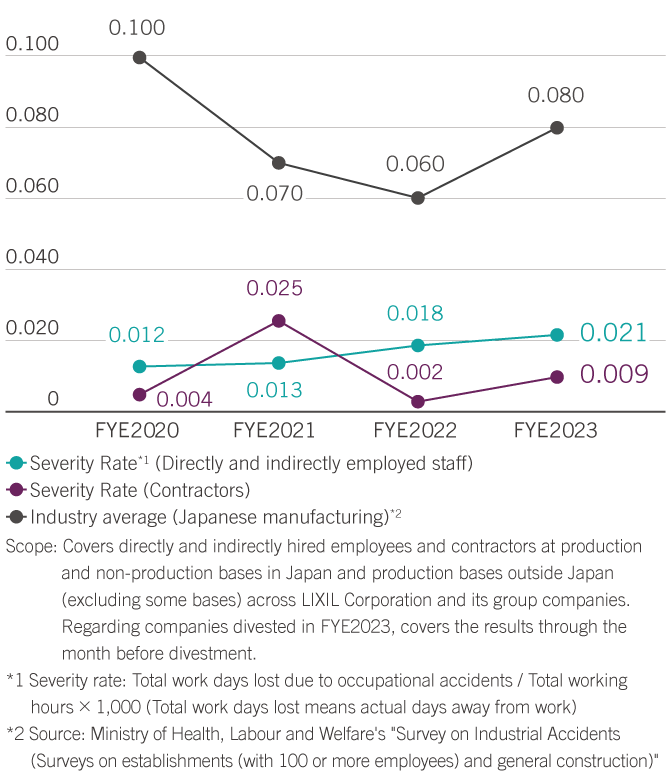

LIXIL monitors various indicators including the lost time injuries frequency rate (LTIFR), the severity rate, and the number of occupational injuries, and introduces measures to help reduce work-related accidents to zero.

Having analyzed all the accidents that have occurred across the company, we set two priority themes for FYE2023: reduction of risks involving "contact with operating equipment” and “cuts and grazes.” This year we have been working to achieve our target of halving the number of those accidents compared to the previous year. We have made progress in some areas, with the number of incidents of cuts and grazes now declining, but the number of incidents relating to contact with operating equipment remains stubbornly flat. In FYE2024, we will focus our attention on “pinching and entanglement” incidents within the contact with operating equipment risk category and seek to reduce those accidents by 30% from FYE2023. We will also promote initiatives designed to reduce accidents caused by “interaction with lifts” to zero because they carry a high degree of risk for occupational health and safety.

LTIFR

Severity Rate

OIFR*

| FYE2020 | FYE2021 | FYE2022 | FYE2023 | |

|---|---|---|---|---|

| Directly and indirectly employed staff | 0 | 0 | 0.007 | 0.007 |

| Contractors | 0 | 0 | 0 | 0 |

Scope: Covers directly and indirectly hired employees and contractors at production and non-production bases in Japan and production bases outside Japan (excluding some bases) across LIXIL Corporation and its group companies. Regarding companies divested in FYE2023, covers the results through the month before the divestment.

* Occupational Illness Frequency Rate (OIFR): Number of occupational illness cases involving days away from work divided by the total working hours then multiplied by 1,000,000

Number of Work-Related Fatalities

| FYE2020 | FYE2021 | FYE2022 | FYE2023 | |

|---|---|---|---|---|

| Directly and indirectly employed staff | 0 | 0 | 0 | 0 |

| Contractors | 0 | 0 | 0 | 0 |

Scope: Covers directly and indirectly hired employees and contractors at production and non-production bases in Japan and production bases outside Japan (excluding some bases) across LIXIL Corporation and its group companies. Regarding companies divested in FYE2023, covers the results through the month before the divestment.

Scope and details of employee-related data >

How We Respond to Occupational Accidents

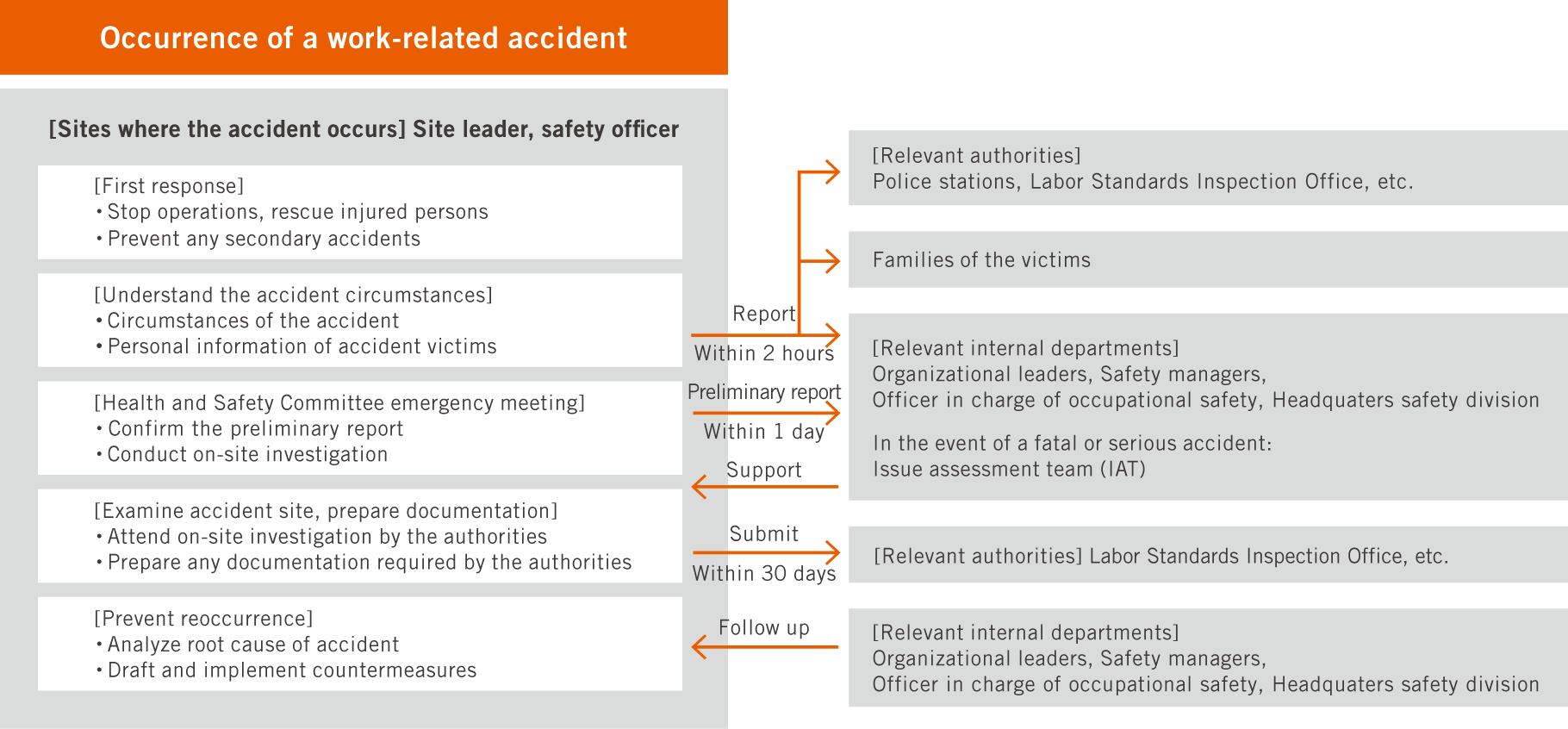

In the event of a work-related accident, we take the following steps to help prevent any secondary or similar accidents.